In processing chickens into products that break down the bird for American consumers into edible forms, Tyson Foods faces one of the gnarliest manufacturing tasks of all. Now part of its answer has been unveiled with the opening of a new, 325,000-square-foot facility in Danville, Virginia, which produces nuggets, patties and other cooked-chicken forms that end up in supermarket freezer cases.

Crucial to the success of the facility is its use of industry-first technology and innovative pilots and prototypes at scale that are supposed to increase the efficiency of these operations by up to 30% over existing plants and cut labor requirements by about 20%.

At the same time, the new, $300-million Danville plant is meant to provide about 400 desirable jobs at a time when the reputation of animal-processing plants has taken hits from the beginning of Covid until now. In its use of automation, for instance, Tyson’s newest plant holds lessons for other manufacturers.

“We’re always looking for ways to make plants produce higher quality and be more efficient,” Bob Parker, vice president of engineering for Springdale, Arkansas-based Tyson Foods, told Chief Executive. “Part of our automation strategy is to try to ensure we have a more reliable supply chain and smarter systems over the top of the automation that we’re putting in with machines, so we continue to ensure our systems are smarter, with operators — as they become upskilled – that are able to operate more effectively and efficiently.”

Tyson could use a win in Danville. The company recently recorded a loss of $648 million for the fiscal year ended September 30, a stark contrast to fiscal 2022, when it earned $3.25 billion, or $9.18 per common share. Annual revenues actually trickled below $53 billion from $53.3 billion the year before, as the company has been buffeted by factors including fewer beef cattle coming to market, higher input costs and a strong U.S. dollar that hindered export opportunities.

The chicken business unit lost $267 million for the fiscal year, and Tyson has been closing chicken plants — including an old, general-processing facility in Glen Allen, Virginia — in favor of a future based on new, more automated facilities like the one in Danville.

A focus on a new, worker-friendly plant also will help the company get past its disappointing record of employee safety and health from the pandemic, including the formation of a betting ring at one of Tyson’s pork plants in Iowa in which seven managers wagered on how many workers there would get sick from the coronavirus. They were fired posthaste.

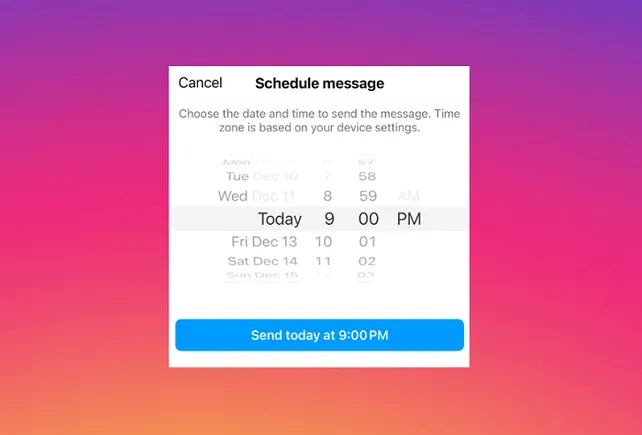

The Danville plant features the latest technology including automated optical visioning and X-ray metal detection to ensure the highest quality. Case packaging and palletizing, storage and retrieval are automated. “An overall process on top of those things automates the entire system and gives real-time data to operators,” Parker explained.

Danville will produce some four million pounds a week of cooked-chicken products once it is at full production in early 2024, the company said, as employment ramps up from the current 270 workers. The plant is the first to be completed and opened under broad investment by Tyson of $1.3 billion in automation across its operations, which is meant to boost safety, increase controllability and enable real-time visibility into production.

Here’s some advice from Parker for manufacturing chiefs, who are increasingly turning to automation to alleviate labor shortages, boost quality and for other reasons:

• Think broadly. “A strategy to implement automation, especially at the scale of a full plant, is a philosophical decision,” Parker said. “You want to make smart, cost-effective decisions, but there are so many other things that go into the benefits of automation and smart systems over the top of it, that you really need to be broad in your thoughts.

“It’s not just about labor reduction. It’s more about the efficiency of the whole operation for upskilled team membesr to be able to see the whole system and operate it more efficiently and effectively.”

• Begin early with upskilling. “Highly technical folks are hard to find, and it takes a while to train them and make sure they’re connected with whatever equipment platforms you’re putting in,” Parker said. “So become an expert in that equipment as it’s being designed and installed.

Designing in, and teaching employees how to use, data dashboards connected to automated systems is a crucial part of that preparation, he said.

• Get a training partner. Operating and maintaining the new plant requires higher-level skills than at Tyson’s pre-existing plants. So the company has partnered with Danville Community College for a technology-training program for higher-skilled jobs at the plant, including maintenance workers who are being relied upon to keep cutting-edge automation running smoothly.

“It’s not just about turning a wrench but also about programming, and in general, running and operating higher-technology systems,” Parker said.

• Keep AI in the dock. Tyson is using AI to help Danville run and is monitoring the newest developments in the technology, including generative AI.

“Were not sure we’ve seen a lot of that hit plant floors yet,” Parker said. “We’re staying on top of what could be implemented and rolled out.”

• Make culture central. Rather than loom as a hammer over the heads of employees as at some existing plants, automation in a new plant can be a strong part of the culture.

“It’s highly automated and purpose-built, and team members are very proud to be in that kind of plant,” Parker said. “You see it in their work and how they maintain the plant. That culture is strong, and automation supports that. It represents the investment the company is making in the facility, and it can make difficult jobs easier.”

The post Tyson Foods Makes Huge Bet On Automation In New Plant appeared first on ChiefExecutive.net.