Ann Clark is not your average, cookie-cutter manufacturer; it is truly a cookie cutter manufacturer.

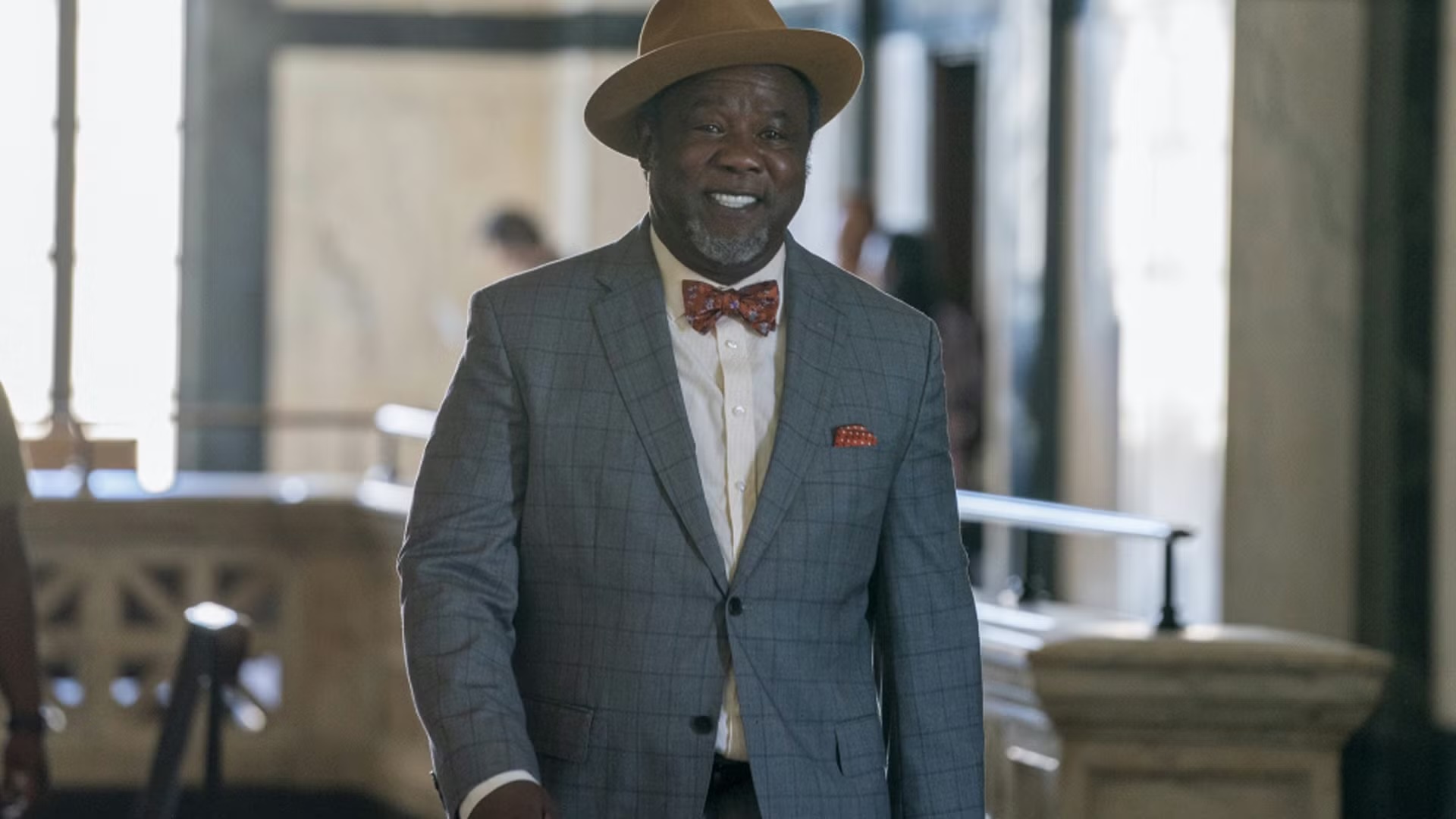

Ben Clark is the CEO of the Rutland, Vermont-based company—the largest cookie cutter manufacturer in the U.S., making more than 700 unique shapes. The company is also a fast-growing producer of food coloring and baking ingredients and supplies.

Clark took over the family business founded by his mother, Ann. Blending her unique folk art designs and custom hand-painted recipe cards, she manufactured her first line of metal cookie cutters in 1989, and the eponymous company was born.

He has since transformed the company through lean manufacturing practices, boosting efficiency and minimizing waste while ramping up production. Under his leadership, the company now sells between 4 and 5 million cookie cutters each year.

Clark has spearheaded the expansion of Ann Clark’s product line to include baking mixes, tools and essentials. The company employs more than 30 people and regularly generates between $10 million and $15 million in annual revenue. Clark spoke with Chief Executive to share his strategy behind transforming and growing the business.

What is the history of your company and how has it evolved over the years?

My parents, Ann and John, started the company in 1989 out of our family garage. What began as a small project has grown into a nationally recognized brand. They launched our first collection of six cookie cutter designs at the Philadelphia Gift Show—and the rest is history.

To support the growth of the family business, I stepped in as CEO in 1998 after working at Black & Decker. One of the most impactful changes I brought with me was the implementation of lean manufacturing. This approach allowed us to create an efficient production system that minimizes waste while maximizing quality and speed.

With my mom and me working side by side, the business has grown to become the largest cookie cutter manufacturer in the U.S., now offering more than 700 shapes. In recent years, we’ve also expanded into new product lines, including premium baking mixes and other essential baking ingredients.

Tell us about your lean manufacturing practices.

At Ann Clark, lean manufacturing starts with listening to the market. By tracking consumer behavior and identifying which cookie cutter designs are most popular, we can accurately forecast demand. This helps us produce the right quantities of each shape—ensuring we meet customer needs while avoiding overproduction.

This system not only minimizes waste but also allows us to be nimble. When a trend pops up, whether it’s a popular holiday shape or a viral design, we can respond quickly and bring products to market faster than ever before.

What advice do you have for manufacturers just opening their doors today?

Start by deeply understanding your customers and the market you’re entering. It’s easy to get excited about the products you want to make, but long-term success comes from solving real needs and adapting to what your customers truly want.

From the beginning, build efficiency into your operations—even small improvements in processes can make a huge difference as you scale. And finally, stay flexible. Markets shift, trends change and challenges arise. The manufacturers who succeed are the ones who can pivot quickly without losing sight of their core values and mission.

What’s next for Ann Clark?

We’re excited to continue expanding our product line and inspiring bakers everywhere. Recently, we launched several cookie mixes, a donut mix and a range of breakfast mixes. We’ve also added new essentials like malted milk powder, flavorings and decorating sugars to help home bakers and professionals elevate their creations.

Looking ahead, we’ll keep innovating while staying true to our roots—creating products that bring people together in the kitchen and make baking even more fun and accessible.