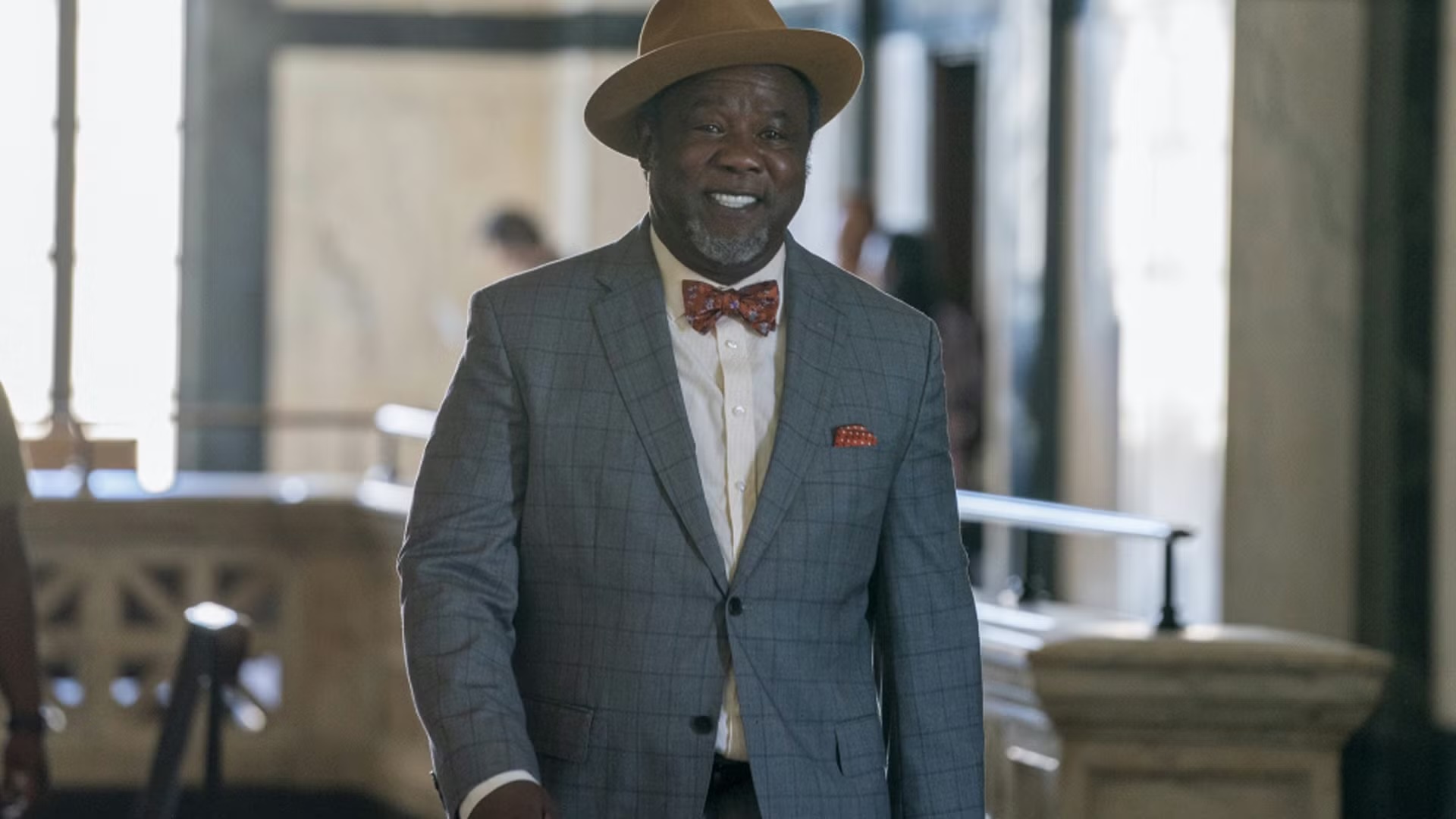

For Fire-Dex, meeting customer needs is quite literally a life-or-death matter. The family-owned manufacturer produces personal protective equipment for firefighters and first responders—gear designed for the most dangerous conditions imaginable. “Everything we make, from turnout gear and boots to helmets and gloves, exists to protect the firefighters and first responders who protect the rest of us,” says Lauren Burke DeVere, president and CEO-elect.

As demand rises for safer, more advanced PPE, Fire-Dex is scaling its U.S. and nearshore manufacturing operations without compromising quality or safety standards. DeVere spoke with Chief Executive about how the company is using lean manufacturing, a mission-first mindset and strong innovation pipeline to fuel growth while building a business designed to last.

Tell us about Fire-Dex and the company’s growth.

Fire-Dex is one of those rare companies where the mission is crystal clear: We serve those who serve. Everything we make, from turnout gear and boots to helmets and gloves, exists to protect the firefighters and first responders who protect the rest of us.

Since our beginnings in 1983, Fire-Dex has come a long way. My dad, Bill Burke, joined the company in 1984, and in 2019 my sister, Taylor, and I were proud to continue the family tradition by joining the organization. It’s been an honor to be on this journey with them.

Today, Fire-Dex is the fastest-growing PPE manufacturer in the fire service, with three U.S. manufacturing facilities, one in Mexico and our sister company Gear Wash—the largest independent PPE cleaning and repair provider in the world.

What’s driving that growth? Innovation and constantly finding solutions for our customers. Recently, we’ve led the way in breakthrough technologies like AeroFlex turnouts for better breathability.

I’m particularly excited about the buzz our garment is creating right now, because there’s never been anything like it before. Heat stress is the leading cause of death for firefighters in the line of duty, and AeroFlex was specifically engineered to combat that heat buildup and exhaustion.

Fire-Dex is also launching the very first garment designed specifically for the hazardous and unusual work that fire investigators do, because we truly are focused on solving a variety of challenges across the fire service, and not just for one specific job function.

Everything we do or make is to better the health of first responders. It’s the reason our line of alternative PPE for non-fire calls has become so popular, and it’s why we offer more turnout options that give female firefighters the fit they’ve been searching for—what we call “gear that gets her.”

Our AI-powered Virtual Sizer tool is another recent innovation aimed at serving customers better. It takes just a few simple inputs like height, weight and a couple of body shape questions, then builds a “digital twin” of the firefighter that’s as accurate—if not more—than the standard measuring process. It means departments can get their whole crew sized in a fraction of the time while cutting down on errors and returns.

Going forward, we aim to build on our U.S. strength with an eye on growth opportunities internationally. And while we’re always exploring how to add more capability and expertise, we’ll continue to take the same thoughtful approach to expansions and acquisitions that we always have, making sure each move can truly strengthen the ways we serve first responders.

How do you make your manufacturing operations as effective as possible?

Our operational philosophy is to build gear that’s worthy of the people wearing it, and to never waste their time waiting for it. That’s why we’ve invested heavily over the years in lean manufacturing, automation and supply chain resilience, so we can keep our promise to deliver quickly and reliably.

Because we own our facilities, we can experiment, pilot and scale quickly, whether that’s bringing a new fabric into production or tweaking a cut-and-sew process to make it more efficient. We’re also not afraid to borrow ideas from outside the fire industry. Sometimes the best ideas can come from assembly lines, surgical suites or even software companies, so we’re quick to adopt anything that helps us deliver a better, faster, safer outcome for customers.

What lessons can you share from running a family-owned company?

Leading a family-owned business has taught me that culture is the air people breathe when they walk through the door. You can feel it in how our associates talk to each other on the production floor, how they show up for one another when life throws them curveballs, and how they take pride in putting their name behind every piece of Fire-Dex gear that we ship.

Our family-first culture is also what has kept us grounded while we’ve scaled. We know our people as individuals, not just by their job titles. We celebrate the promotions and the babies and the anniversaries. I think that kind of support feels good, and it’s good for our business, because when your team knows you’ve got their back, they’ll go to the mat for your customers.

There’s a unique advantage, too, in that we get to play the long game. We don’t have to chase short-term wins at the expense of doing the right thing. If a big investment in automation or a new product line will pay off five years from now, we can go for it. That freedom to think generationally, or to imagine the company we want our kids and grandkids to inherit, changes how we weigh risk and reward.

At the end of the day, running Fire-Dex is about building something that lasts, something that stays true to the fire service and something that our extended Fire-Dex family can be proud of decades from now.

What’s does the future hold for Fire-Dex?

I don’t say this lightly, but it does feel like we’re just getting started in some regard. In other words, Fire-Dex has had an incredible run to get to where we are, but we see a lot of runway still ahead.

Our goal is to keep growing at a double-digit clip year after year. And we’re going after that in two ways: by continuing to build organically, and by adding more great companies to our Fire-Dex and Gear Wash family. A conversation we keep having is, is it time to take our manufacturing expertise and our service models to more parts of the world, where firefighters face the same risks and need the same protection?

In regard to the PPE world, the industry is changing fast and we’re going to stay at the forefront of that curve. That means more gear that thinks ahead of the dangers that first responders encounter, and more digital touchpoints that streamline the experience of working with a manufacturer like Fire-Dex.

I see us scaling everything that’s already working, like our manufacturing muscle, service network and innovation pipeline. We have a track record for pairing fresh ideas with proven technologies so firefighters can do their job more safely and efficiently. It always comes back to our mission of serving those who serve. That’s our North Star, and it’s going to keep guiding the decisions we make.